Every day we see more and more water blocks being offered for sale on the internet. Some are bad, some are OK, some are good and some are excellent. We hope to give you a basic understanding of how the thermo dynamics of the exchanger work and what constitutes are good design.

Two elements control the efficiency of the water block (herein the exchanger). The coolant and the exchanger design. The coolant is based on its thermal convection coefficient and pressure. The exchanger is based on its thermal conductivity properties and contact area ( total area within the exchanger that the coolant is in contact with).

Most of the systems out there are using plain old tap water. Once everyone takes apart the system after a period of use they will discover just how corrosive good old water is when the system is "open" verses and sealed vacuum system. We always add at least 15% glycol (antifreeze) for it's anti corrosion properties to distilled bottled water purchased at the corner store. Now we all know that adding a even a little glycol to the water reduces the efficiency but the anti-corrosion out ways the efficiency loss.

Water has amazingly superior heat transfer properties compared to virtually any other liquid cooling medium - far superior to glycol-based coolants. Water has almost 2.5 times greater thermal conductivity compared to any glycol coolants. Mixtures of glycol and water have nearly proportional improvement due to the addition of water. The convection coefficient of liquids in a tube is a complicated relationship between the thermal conductivity, viscosity of the liquid, and the channel area that determines the amount of turbulent flow. Even though water has excellent heat transfer properties in its liquid state, it's very high surface tension makes it difficult to capture energy from the exchanger surface. Since 50/50 glycol solution has about 4 times the viscosity and only 70% of the thermal conductivity of water, the thermal convection coefficient for a 50/50 glycol solution is approximately 50% of the coefficient for water. But even that can be over come. Most of your local auto parts store carry what is called WaterWetter® manufactured by Redline Oil . Red Line's unique WaterWetter® reduces the surface tension of water by a factor of two, thus smaller surface "bubbles" form against the exchanger walls, allowing more contact area between the water and exchanger walls to transfer heat.

In a ambient temperature cooling solution, we tested a dozen coolants and found the most efficient and least corrosive combination to be 85% distilled water, 15% common glycol, and 1oz. of WaterWetter® per quart of coolant mixture.

Exchanger materials are as important to an efficient exchanger as the coolant. This is where the thermal conductivity properties come into play. Aluminum is 155W/m˚C and Copper is 384W/m˚C. As you can see it is a no brainer, with 2.5 times the ability to transfer heat, copper is the natural material selection.

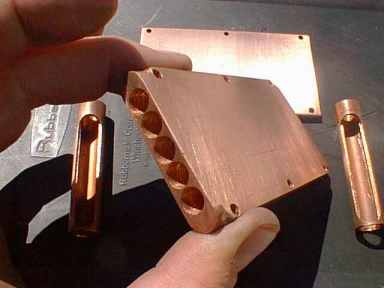

Now we get into the basics of the exchanger design and what make them efficient. As we talked about earlier about the convention coefficient (the ability to absorb heat), these basic principles are proportionally effected by pressure and contact area. We can overcome surface tension by forcing greater area of liquid contact with pressure, but in an electronics cooling package, that is a little foolish due to the increased probability of leaks. This leaves us with the contact area or the surface area of the inside of the internal channels of the exchanger. These two designs, one hand made for a Slot 1/Slot A CPU and the other for a Socket CPU manufactured by DangerDen provide the maximum internal surface area for their compact designs.

The Slot1/SlotA exchanger has 18.78 sq.in. and the DangerDen a-MAZE-ing Socket exchanger has 9.86 sq.in. of coolant contact area The typical designs offered on the internet are aluminum or copper with two 3/8" holes drilled in them. The Slot1/SlotA units having +/- 8.2 sq.in of area and the Socket units +/- 4.125 sq.in. Basically what you are getting is 40% to 50% of the potential available if manufactured properly, when not looking at what you are buying. Spend the extra bucks and get the efficiency of the copper water blocks and cold plates with a good internal design.

Using an exchanger like show above, along with the suggested coolant mixture, you should see a 2˚C to 3˚C improvement over typical internet units and if you throw in a 78W peltier the gains will be 5˚C to 8˚C more cooling power over the typical internet offerings.

Back to Home Page