With a 48mm spacing between the SC242 Slots, there is NO room for any type of large heat sink and fan. Now add a 12.5MMx50MMx100MM cold plate. A 35MMx63MMx100MM heat exchanger and two 40MMx40MMx3.6MM ICE-71™ peltiers from TE Distributing http://www.tedist.com/specs/index.htm. This prevented the use of thicker heat exchangers and heavy insulation.

No pictures of the cold plate assemblies. The heat exchangers were constructed out of 35MMx63MM aluminum bar stock, cut 100MM long. After the holes where matched to the cold plate and drilled and tapped, it was apparent that I could drill four 7.6MM holes lenghtwise (100MM side) and the tap the holes a the open end and install 3/8" brass pipe plugs. I then drilled an additional two 7.6MM holes from the top to connect the four holes drilled lenghtwise and tap then for the 3/8" pipe to 1/8" tubing 90° fittings. Four peltiers were then sandwiched between the two heat sinks and cold plates with heat paste and six #6x32 screws. To attach the Coppermine® to the cold plate, I used #6x32 screws by taking a flat file and filing the treads off the screw just below the head. I used #6 nylon washers to insulate the screws from the PCB. The whole assembly was then "encased" in 3/8" high density, closed cell foam, by cutting pieces and using black silicone to "glue" them together. This sealed the PCB and CPU core from the ambient air prevent any condensation.

The radiator was picked up from a junkyard and was out of a motorcycle, it is a two pass unit so I installed a 5/8" hose fitting in the 1st pass section and a 1/8" hose fitting in the 2nd pass area. 28Ga sheet metal was used to make the fans shroud and the pieces were pop-riveted together. Two 120MM, 115CFM, 12V fans were installed in the back of the case and then radiator and shroud were attached over them with #12 x 3/8" sheet metal screws. The air direction blows through the radiator section pulling ambient air from outside the case. The pump selected is a Little Giant CAT# 588001, Industrial mild corrosive chemical pump. It is rated at 160GPH at 2' of head pressure. I went to the local plumbing supply and picked up a 4"x4"x1" PVC Tee fitting to use as the storage tank. The ends are 4" slip to 3/4" pipe. Brass fittings where then used to adapt the system plumbing. A mixture of 20% Glycol & 80% Water with 1oz. of Redline® Water Wetter® was used as the primary coolant.

The peltiers are powered by a 35amp, 0-15v variable power supply which I built and installed in the case.

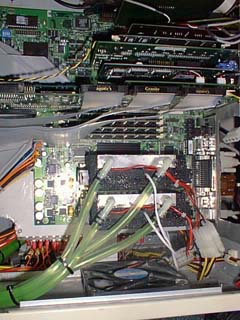

The white wires you see in the picture of the assembled unit are the temp probes which are the two LCD readouts. With this water cooled system, maintaining CPU temps of -15C to -20C under full load (running two Seti@Home at the same time) was easy to maintain. The setting shown above are at 14.2V, pulling 7.1amps for each of the four ICE-71™ TEC's.

Back to Home Page